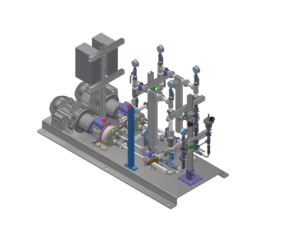

The Trim Squirt Water Supply System includes –

Gatewood OptiMaxx Model TSS

It is an integrated spray water pumping system designed specifically for use with paper machine Trim Squirt Systems. This system consists of two variable speed Hydracell pumps (in a duty/standby configuration), and a duplex filtration system. All components are mounted into one compact assembly that is complete and ready for installation. The System provides a clean, high pressure, reliable, smooth and consistent water flow to the trim squirt nozzles, thereby helping to reduce downtime. The system is designed to be able to feed single or multiple nozzles.

Hydra-Cell® pumps

These are the heart of our OptiMaxx Trim Squirt Water Supply system as they provide a pulse-free reliable flow to the trim squirt nozzles. The Hydra-Cell® pumps are far more efficient than the centrifugal pump counterparts often used in the application. Hydracell pumps are small, compact and use much less energy for the same output. For example, a 5 HP motor can provide the same required flow and pressure as a centrifugal needing as much as 15.0 HP. In a 24 hour/7 day a week operation, the energy savings are substantial. The ease of maintenance and low cost of parts offer other advantages.

Minimum required inlet pressure

Required inlet pressure may be greater than 50psi depending on field suction piping length, size and arrangement. Separate booster pumps available if required.

Variable Frequency Drive Control System

The Trim Pump System described above includes 2 Variable Frequency Drives (VFD’s) mounted on the skid and pre-wired to the motors. The VFD’s provide local or remote on/off control for each pump, as well as local or remote variable speed control of the motors. In local, the speed of the motors is controlled by pushbuttons on the front of the VFD. In remote, a 4-20mA input control signal can be supplied to the VFD to automatically vary the speed (and flow rate) of the pump remotely for variable flow rate applications (e.g. feeding more or less trim squirt nozzles). Both VFD’s and pumps function independent of each other and each would require their own power supply and any digital or analog I/O signals.The Electrical control system also includes a pressure transducer on the common discharge, as well as a flow switch for remote monitoring, alarm and control capability.

Features:

- All Stainless Steel 304 / 316 piping, base, and all wetted metal materials.

- Two variable speed, Hydracell Pumps, with pulsation dampener for pulse-free flow.

- Flow range capable of 0.44 to 8.8 GPM. Locally or remotely adjustable by 2 Variable Frequency Drives with 4-20mA control signal capabilities.

- Nominal application operating pressure of 250-400 psi, Maximum design of 1500 psi (3.87 GPM max), complete with integrated pressure control

- Pump Motors to be 480VAC/60/3 or 575VAC/60/3, 5.0 HP Inverter Duty

- VFD’s to be NEMA 4X (IP65), 5.0 HP, 480VAC or 575VAC/60/3 in/out

- Stainless Steel pressure regulating valve on discharge of each pump.

- Integrated, duplex Filtration station including two filtering units with changeover capability, glycerin filled stainless steel pressure gauges and stainless steel ball valves

- Complete assembly pre-wired and piped for easy installation

- Compact design: Overall dimensions 28” width 64”length 45” height